We print on a wide range of flexible supports, such as Paper, PET, PP, PA, PE,

Aluminum, etc. We laminate without solvents to create multi-layer structures,

selecting the most suitable materials, taking into account the application, packaging system

thermal/ barrier properties and the desired effects and finishes.

We use materials, films, inks and adhesives, suitable for food contact,

supplied by leading suppliers in the market.

Our Products

-

Sustainable Solutions: Monomaterial

-

Sustainable Solutions: Paper-based

-

Sustainable Solutions: Compostable

-

Vertical flowpack

-

Pharmaceutical blister & Alu Strip

-

Doypacks and Pre-made Pouches

-

Tray Lid film

-

Horizontal flowpack

-

Cup Lid film

-

Sachet & single-dose packaging

-

Stick pack

-

Wrap Around label

-

Twist film

-

Eco Packaging

-

Customized solutions

Overprinting and recycling

New solution to correct your printed reels and insert promotions.

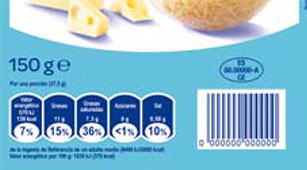

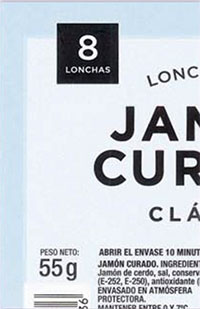

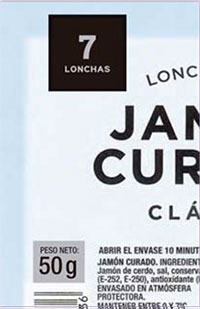

This service consists in overprinting on the surface of already printed reels. It allows adding, changing or deleting texts, allowing therefore the utilization of reels that otherwise would have been obsolete due to changes in legislation, ingredients, barcode, weights, nutritional values, etc.

The overprint is done in 2 colors: a metallic color (silver or gold) acts as a patch to suppress the error and a second color rewrites the desired information.

-

Before

-

After

-

Before

-

After

Finishes

and properties

We advise you and offer the best solutions in terms of properties and finishes, which best suit your needs, taking into account the product to be packaged, packaging equipment, aesthetic requirements, functionalities required, etc.

Finishes:

The finishes provide an experience, not only visual,

but also sensorial/ tactile to the final consumer. The

application of special lacquers can enhance the marketing

message, conveying a feeling of softness, roughness, etc.

- Visual effects:

- Opaque/ metalized

- Matt / gloss

- Pearlescent

- Paper look (Kraft)

- Tactile effects: simulation of multiple textures:

- Slip/ anti-slip

- Paper touch, among others.

Properties

-

Barrier

Barrier to UV, Aroma, O2, humidity: Aluminum, metallized, Alox, Siox, EVOH, PVOH, etc.

-

Sealing

Good hot-tack, high speed sealing, in environments with dust particles, at low temperature, etc.

-

Closing

Easy-open, peelable, reclosable, on APET, etc.

-

Heat treatment

Resistance to pasteurization treatments, sterilization, microwave, etc.